ˆ

News box EN

PIROLIZA Techtrans – Rubber to Oil Technology

29-02-2016 | print

If you look for a very profitable business, if you are not afraid of challenges and if you want to create a stable, far-reaching enterprise, then you are at the right place!

Our company was established in 1989 and since then we have been developing our production of screw conveyors, transport devices and systems of thermo-catalytic processing of rubber waste and car tires into full-value fuels such as

• wide oil-petrol fraction: hydrocarbons C4 – C30

• gas fraction: hydrocarbons C2 – C4

Moreover, the system we produce make it possible to obtain full-value carbon black, which can be processed in chemical industry or directly briquetted and burned to generate heat

Steel is another important material that can be obtained with the use of our systems

We offer two types of pyrolysis systems created in accordance with our own design:

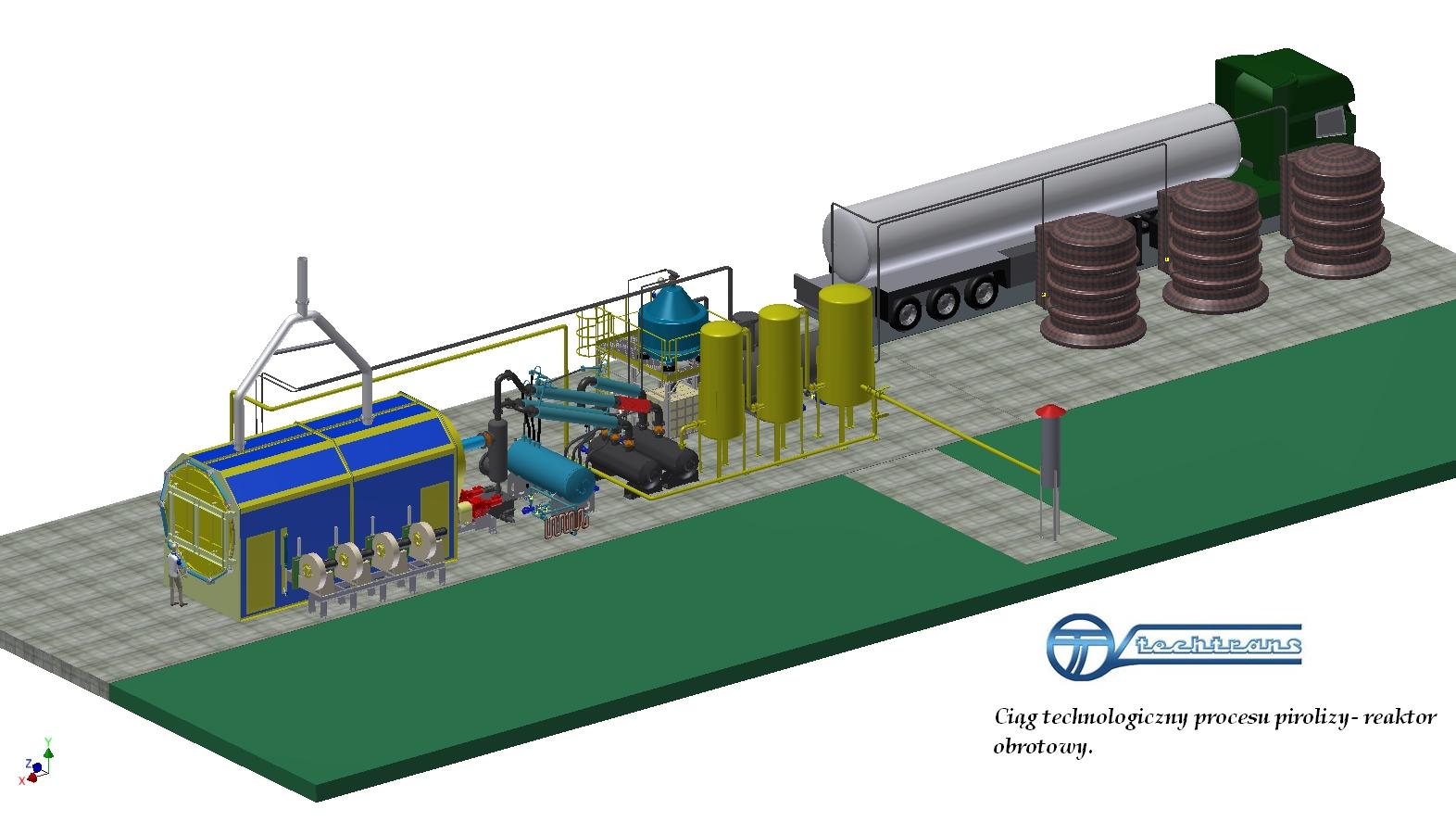

*System with a rotary reactor - the most popular version is able to recycle 12 tons of rubber feed per day. The system is equipped with all devices required to perform the whole process. At the client’s demand, we may set and deliver all peripheral devices and prepare the entire facility, from the design to the commissioning. The offer meets all ecological standards, and what is most important - if it is not subsided, it starts to bring profit after just 2.5 years of functioning.

*The most modern system with tunnel reactor, which in its standard mode of operation is capable of processing up to 20 tons of fragmented feed per day. The system meets even the most rigorous international standards, including those in force in Arabic countries. The device does not produce any emissions or odors. It is very popular, especially in the Western Europe.

Each type of our systems can be set up to operate with power generating installations, which makes it possible to burn the produced oil directly in the combustion engines. 200 liters of oil enable the production of 1 MW of electric current.

Some figures related to our systems and feeds:

- 12 tons of rubber - rubber feed for free or for a surcharge

- our systems are heated with oil they produce

- they can be operated by few employees for 24 hours/a day

Daily production in the case of the rotary system:

- 5.5 tons of oil or 55 MW of electric current per day

- 4 tons of carbon black for briquetting or processing in our other dedicated systems that require active carbon black

- 1.2 tons of steel

As you may see, considering the waste processing industry, the business is very profitable and far-reaching.

To conclude, some important information:

- Price of a system with rotary reactor capable of processing 12 tons of feed per day is 800 thousand Euros net

We are at your disposal. Complete systems with revolutionary automatics and safety devices are produced in Poland, at our production facilities located in Jasień near Zielona Góra. We are able to perform the entire facility preparation process and obtain all required permits in 3 months.

Our company was established in 1989 and since then we have been developing our production of screw conveyors, transport devices and systems of thermo-catalytic processing of rubber waste and car tires into full-value fuels such as

• wide oil-petrol fraction: hydrocarbons C4 – C30

• gas fraction: hydrocarbons C2 – C4

Moreover, the system we produce make it possible to obtain full-value carbon black, which can be processed in chemical industry or directly briquetted and burned to generate heat

Steel is another important material that can be obtained with the use of our systems

We offer two types of pyrolysis systems created in accordance with our own design:

*System with a rotary reactor - the most popular version is able to recycle 12 tons of rubber feed per day. The system is equipped with all devices required to perform the whole process. At the client’s demand, we may set and deliver all peripheral devices and prepare the entire facility, from the design to the commissioning. The offer meets all ecological standards, and what is most important - if it is not subsided, it starts to bring profit after just 2.5 years of functioning.

*The most modern system with tunnel reactor, which in its standard mode of operation is capable of processing up to 20 tons of fragmented feed per day. The system meets even the most rigorous international standards, including those in force in Arabic countries. The device does not produce any emissions or odors. It is very popular, especially in the Western Europe.

Each type of our systems can be set up to operate with power generating installations, which makes it possible to burn the produced oil directly in the combustion engines. 200 liters of oil enable the production of 1 MW of electric current.

Some figures related to our systems and feeds:

- 12 tons of rubber - rubber feed for free or for a surcharge

- our systems are heated with oil they produce

- they can be operated by few employees for 24 hours/a day

Daily production in the case of the rotary system:

- 5.5 tons of oil or 55 MW of electric current per day

- 4 tons of carbon black for briquetting or processing in our other dedicated systems that require active carbon black

- 1.2 tons of steel

As you may see, considering the waste processing industry, the business is very profitable and far-reaching.

To conclude, some important information:

- Price of a system with rotary reactor capable of processing 12 tons of feed per day is 800 thousand Euros net

We are at your disposal. Complete systems with revolutionary automatics and safety devices are produced in Poland, at our production facilities located in Jasień near Zielona Góra. We are able to perform the entire facility preparation process and obtain all required permits in 3 months.